Does your business involve cutting, trimming, sanding and grinding of wood, rocks, cement and other construction materials? If yes, dust emission and dust control in the job site could be your major problem.

Why Dust Control is Important

Dust is one of the many hazards in an industrial workplace. Depending on its size and amount, it can cause serious problems to your machinery, product quality and workers’ health. Is effective control can therefore impact your business positively.

Studies show that dust, when left unattended, can penetrate and build up inside machinery components resulting in premature wear and tear. Additionally, dust with carbon fiber content can produce rust in aluminum parts and contribute to the dismantling of bonded parts both in your machinery and products.

Health Risks Caused by Dust

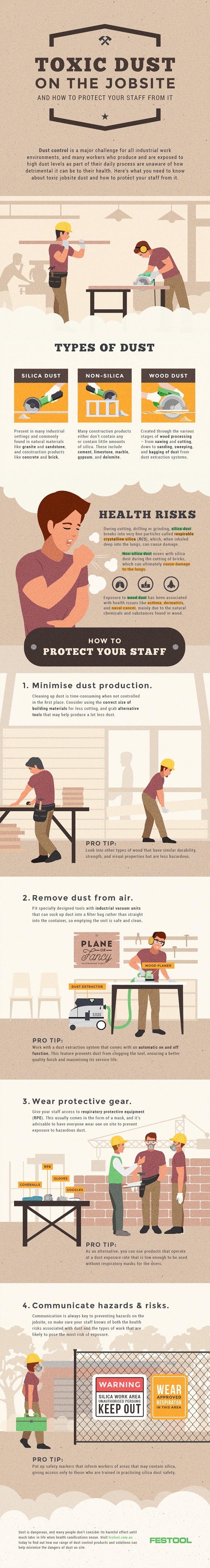

There are at least three types of dust which pose health risks on industrial job site workers. These are the wood dust, silica dust and non-silica dust. Non-silica dust is found in granite, sandstone, concrete and brick. Meanwhile, silica dust is found in cement, limestone, marble, gypsum and dolomite.

When inhaled, both silica and non-silica dust cause severe damage to the lungs and the entire respiratory system. Wood dust, on the other hand, causes asthma, dermatitis, nasal cancer and eye irritation.

How to Control Dust in Your Job Site

Dust control includes practices which reduce or prevent the spread of dust in the air or in surfaces. Any dust control method will work depending on the size of your business and the type of activities done in your job site. Nonetheless, here are basic tricks you might want to try.

1) Selection of less hazardous materials.

Before starting a new project, evaluate the materials you will be using. If they emit a lot of dust during production, research potential replacements which won’t affect the quality of your end product. Also, use only materials that are already the right size for the project to reduce the cutting or grinding process.

2) Use of efficient tools.

Look for alternative tools that are capable of reducing the amount of dust produced while you are working on your project. In connection to this, you might want to invest on quality tools which allow easy and accurate cutting, grinding or sanding for reduced dust emission.

3) Have a dust extraction system.

There are vacuum units that you can use to suck all the dust floating in the air. Consider models which can be easily connected to your tools for the quick suction of dust while you are working. This can substantially lessen the amount of dust floating in your workplace.

Successful dust control on your job site might require your business to invest in additional tools and quality materials. Needless to say, its benefits will overshadow your expenses in the long run as you will have healthier workers who can contribute to increased production. You are less likely to spend on machinery repair or purchase as well since your onsite equipment will be able to perform longer without dust penetrating and destroying their parts.